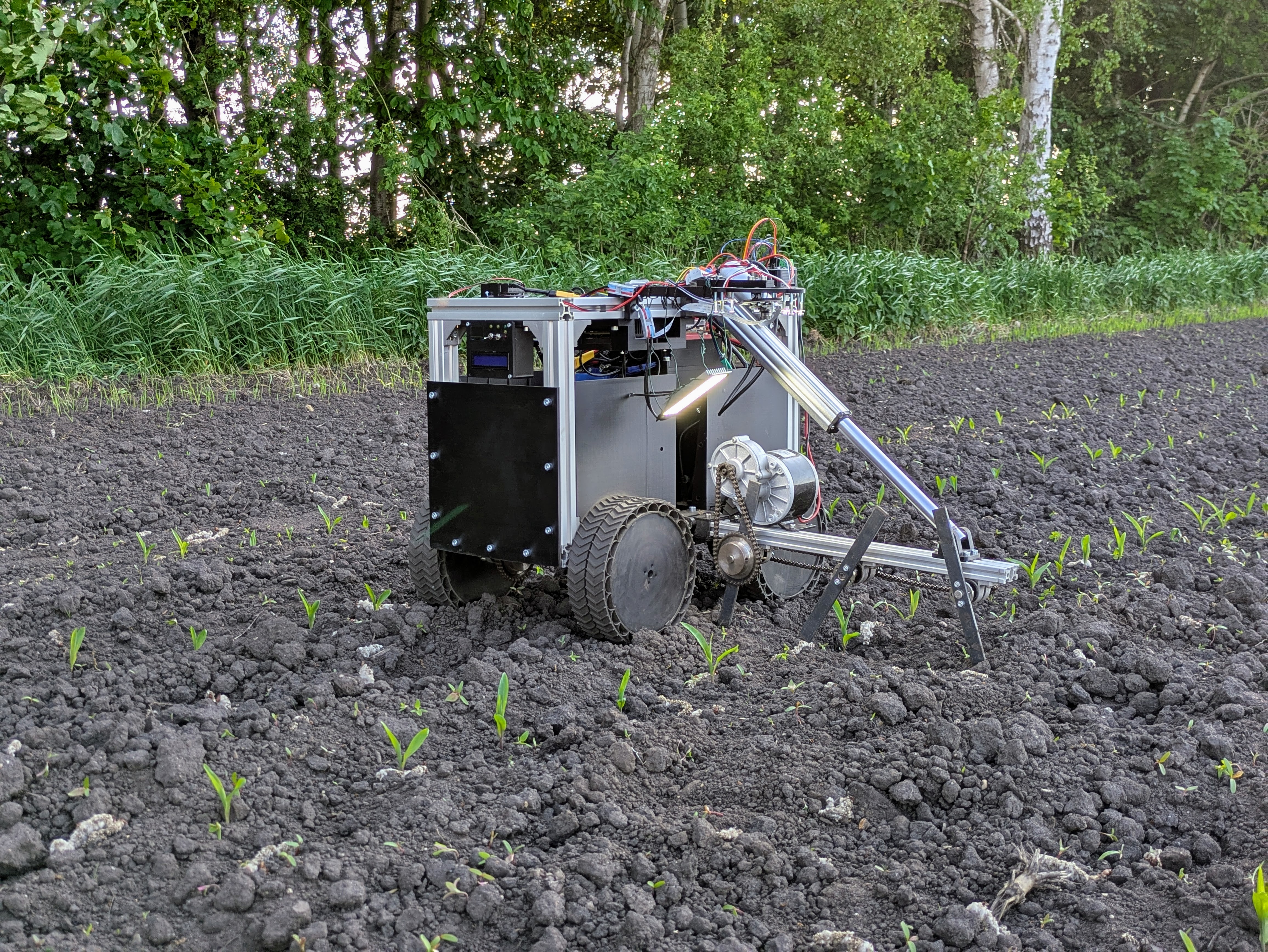

R3 represents a complete redesign from the ground up, moving beyond R2's proof-of-concept approach to create a full-featured technology demonstrator with practical capabilities. While R2 successfully demonstrated that cost-effective AI-based weeding robots are feasible , R3 focuses on developing and testing novel methods that could potentially replace current industry approaches. Key advances over R2: R3 introduces precision weeding with individual plant targeting, replacing R2's broad mechanical removal approach. A patented plant identification method combines object detection with conventional algorithms—more efficient and adaptable than the instance segmentation models used in current commercial systems. Instead of mechanical blades, R3 employs an innovative thermal weeding system using a heated contact head, offering a safer and more cost-effective alternative to laser-based systems while maintaining precision. The robot features full autonomous navigation with RTK-GPS and camera-based row tracking, nearly 4 kWh of LFP battery capacity (~5 hour runtime), and a web-based user interface for real-time control and monitoring. Weighing 55 kg and measuring 700×550×100 mm, R3 has been validated through laboratory tests and simulations on archive footage. Field tests on maize crops are planned for spring 2026 to evaluate the new methods under real conditions. R3 is participating in Jugend forscht 2026.

In agriculture, chemical herbicides are currently used to combat unwanted companion vegetation. These are only partially biodegradable and otherwise enter the natural cycle, potentially harming soil organisms and chemically polluting groundwater. WeedXtract R3 was developed to answer the question: Is it possible to develop a cost-effective, efficient, and autonomous robot for precise treatment of unwanted companion vegetation? Through innovative new approaches, the robot aims to be both safer and more cost-effective than conventional systems. It was conceived as a technology demonstrator to test new methods that could complement or replace current precision weeding technologies.

A novel method for plant identification was developed, for which a patent application has already been filed. This combines targeted use of object detection to detect the crops and a general detection of vegetation using conventional approaches. The method works in several steps: First, crop plants are identified using a YOLOv11-based object detection model. Then, general Vegetation is detected using a conventional algorithm. Finally, the identified crop plants are subtracted from the total vegetation, leaving the weeds that can then be targeted. Advantages of this method: It is more computationally efficient than instance segmentation models, requires smaller training datasets (trained on over 3,000 images with 99.4% accuracy), is easier to adapt to other crops, and achieves an inference time of only 50ms on the Jetson Orin Nano. Most importantly: the false negative rate can be controlled more easily which helps prevent damage to crops.

An innovative thermal method was developed for weed control that sits between existing mechanical and laser-based approaches. A heating head heated to 300°C is pressed directly onto the plant for about 3 seconds. This heats the proteins in the plant cells above 70°C, causing them to denature and the plant to die. The heating head consists of a 60mm x 60mm x 10mm aluminum block with six 40W heating cartridges. This temperature is below the ignition temperature of typical field vegetation, eliminating fire hazards. Advantages over laser systems: More energy-efficient, safer (no laser safety measures required), technically simpler, more cost-effective, and enables autonomous unattended operation. Tests on grass and dandelions have already demonstrated the method's effectiveness. The heating head is precisely controlled over the weeds via a lead screw on linear rails, then pressed onto them using a linear actuator (160 mm/s, up to 200 mm stroke).

Dimensions & Weight: 700 x 550 x 100 mm, approx. 55 kg

Power Supply: Two custom-built LFP batteries (Lithium Iron Phosphate) with a total capacity of nearly 4 kWh (1.35 kWh at 12.8V and 2.56 kWh at 25.6V). Average power consumption: ~500W without drive, ~800W with drive. Potential operating time: approximately 5 hours.

Control: Jetson Orin Nano as main computer, ESP32 S3 microcontroller for the weeding mechanism, Raspberry Pi Zero for GPS processing. Two IMX219 cameras (downward and forward-facing) with 2 × 100W LED floodlights each for day and night operation.

User Interface: Web app in local WiFi network with real-time metrics, control options, and calibration parameters.

Drive: Temporarily via controlled carrier platform with four tractor wheels, two 24V DC motors, and differential steering. Own drive system in development (planned February 2026).

The development of R3 can be considered successful, however it is still ongoing. The tested methods appear promising and address key challenges in precision weeding:

Next Steps: Extensive field tests on maize fields are planned for spring 2026 to validate functionality under real conditions. These will systematically evaluate actual field performance, reliability of plant identification under various conditions, and crop plant protection. Integration of a dedicated drive system (February 2026) as well as improvements in weather resistance and maintainability are also on the roadmap.

R3 is participating in Jugend forscht 2026 and demonstrates the potential of new approaches for environmentally friendly agriculture.

R2 is a compact field robot that uses AI to detect maize plants and remove unwanted companion vegetation mechanically between them. The main goal with R2 was to demonstrate, that such a robot can be developed cost effectively, which was succesfully achieved as the robot costs under 2000€ to build before any scaling. The platform prioritizes a practical, modular design: it combines on‑board object detection with dedicated microcontroller‑based subsystems for actuation and control. R2 weighs about 18 kg and measures roughly 37 × 40 × 50 cm (W × H × D). The system is split into subsystems: object detection (main computer), weed removal, drive and power. A central microcontroller aggregates telemetry and mediates inter‑subsystem communication.

The object detection model is based on Yolo v11 and trained on a custom dataset of over 3000 labeled maize images. It is running on an Nvidia Jetson Orin Nano at around 25 frames per second. In tests the model achieved about 99.4% accuracy. Detections are aggregated across frames and adjusted with the robot's relative motion to reduce single-frame errors.

Removal is performed by three vertically rotating flail blades operating at about 100 RPM, driven by a 250 W brushed motor via chains. The blades are mounted on an aluminium extrusion that can be lifted by a linear actuator to avoid maize plants; the blades are stopped while the actuator is raised. Both the actuator and motor are controlled via BTS7960 H‑bridge drivers from the subsystem microcontroller.

R2 is driven by two 120 W brushed motors (front and rear). Motor control uses PID loops and magnetic encoders for speed feedback. Steering is not yet implemented. The 3D‑printed wheels feature a rigid PLA core with a softer TPU outer profile to improve traction and damping (diameter 20 cm).

Power is supplied by four prismatic LiFePO4 cells in series (3.2 V, 105 Ah each), providing a 12.8 V pack (~1.344 kWh). The pack is protected by a BMS with integrated fusing and an additional PV fuse is placed in series. The robot draws up to ~35 A in operation, giving an estimated runtime of roughly 6 hours; the electrical design uses a safety margin of 2.

At Jugend forscht 2025 R2 won on the regional and statewide level and participated at the national final. At the final as well as in the rounds before it also won the "Umwelttechnik" prize.

R1 was an early proof-of-concept prototype used to validate the basic approach, logic and object detection models. It demonstrated the feasability of privately developing such a robot. Lessons learned from R1 shaped the architecture used in R2.